Call: 08045477394

Industrial Wastewater Treatment System

200000.00 INR/Unit

Product Details:

- Material Stainless Steel / Mild Steel

- Membrane Size 8 inch / 4 inch (as per requirement)

- Weight Variable depending on capacity

- Dimension (L*W*H) Customized as per requirement

- Membrane Quantity Variable as per system design

- Capacity 500 LPH - 100000 LPH

- Color Industrial Grey/Blue

- Click to View more

X

Industrial Wastewater Treatment System Price And Quantity

- 200000.00 INR/Unit

- 1 Unit

- 5°C - 50°C

- Industrial Effluent/Raw Wastewater

- <80 dB

- Meets Local Environmental Compliance

- Available

- 2-12

- MBR/RO/UF/MBBR/Clarifier Combination

- Available

- Integrated

- PLC/Relay Based

- Provided with dewatering facility

- Semi-Automatic/Automatic

- Up to 95%

- Continuous/Batch

Industrial Wastewater Treatment System Product Specifications

- Variable as per system design

- 8 inch / 4 inch (as per requirement)

- Stainless Steel / Mild Steel

- Customized as per requirement

- Variable depending on capacity

- 220V/380V/440V (50/60Hz)

- Industrial Grey/Blue

- 500 LPH - 100000 LPH

- Industrial Wastewater Treatment System

- 5 - 25 kW (Depending on plant size)

- Effluent treatment for industries

- Removes contaminants and treats industrial wastewater

- 2 - 8 weeks

- 5°C - 50°C

- Industrial Effluent/Raw Wastewater

- <80 dB

- Meets Local Environmental Compliance

- Available

- 2-12

- MBR/RO/UF/MBBR/Clarifier Combination

- Available

- Integrated

- PLC/Relay Based

- Provided with dewatering facility

- Semi-Automatic/Automatic

- Up to 95%

- Continuous/Batch

Industrial Wastewater Treatment System Trade Information

- 1 Unit Per Day

- 7 Days

- All India

Product Description

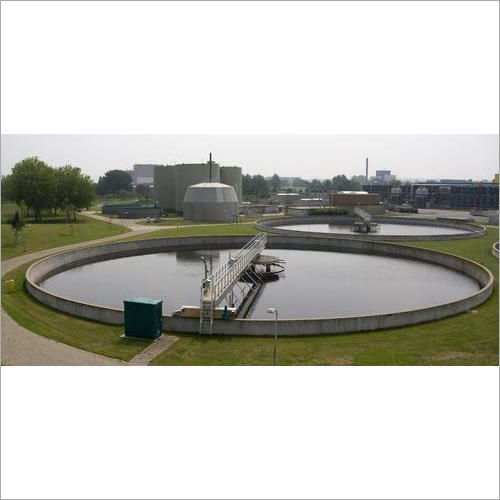

20KLD Industrial Wastewater Treatment System

Our designed 20KLD Industrial Wastewater Treatment System is popular in the market for its high quality and optimum performance. It is helpful in separating suspended solids from the water. This 20KLD Industrial Wastewater Treatment System is accustomed with long lasting service life and simple features. It is available in different sizes, features and finishings.

Other Details

Material : Metal

Usage : Industrial

Voltage : 220-380 volt

Warranty: 1 Year

Features : Durable, Corrosion Resistance

Advanced Wastewater Treatment Technologies

This system leverages a powerful combination of MBR, RO, UF, MBBR, and clarifier technologies to ensure comprehensive removal of contaminants from industrial wastewater. The integration of these methods maximizes purification, optimizes water recovery up to 95%, and helps industries consistently meet stringent environmental discharge standards.

Customizable Design & Robust Engineering

Each treatment plant is customized to meet specific industrial requirements, with flexibility in dimensions, membrane size, capacity, and automation grade. Using quality stainless steel or mild steel, the system resists corrosion, operates reliably within a pH range of 2-12, and maintains performance in ambient temperatures from 5C to 50C.

Seamless Operation & Minimal Maintenance

Our systems feature intuitive PLC or relay-based control panels that offer easy operation and real-time monitoring. The integrated chemical dosing and sludge dewatering solutions reduce manual intervention, while well-planned installation services ensure trouble-free commissioning and maintenance for optimal plant longevity.

FAQs of Industrial Wastewater Treatment System:

Q: How does the industrial wastewater treatment system work?

A: The system operates by channeling industrial effluent or raw wastewater through a series of advanced processes, including membrane bioreactors (MBR), reverse osmosis (RO), ultra-filtration (UF), moving bed biofilm reactors (MBBR), and clarifiers. These technologies remove contaminants, reduce sludge volume, and recover up to 95% of water for reuse or safe discharge.Q: What types of industries can use this wastewater treatment system?

A: This treatment system is designed for a wide range of industries, including manufacturing, pharmaceuticals, textiles, chemicals, and food processing, where efficient effluent treatment is essential to meet local environmental compliance standards.Q: When is it suitable to choose semi-automatic versus automatic operation?

A: Semi-automatic systems are ideal for facilities seeking operator involvement and manual control for flexibility, while automatic systems are better suited for operations requiring minimal supervision, consistent performance, and greater process automation for higher treatment capacities.Q: Where can the system be installed, and are installation services available?

A: The system can be installed at any industrial site, with installation services provided throughout India. The plants design and footprint are fully customizable to suit site-specific requirements, ensuring seamless integration with existing infrastructure.Q: What is the process of handling and dewatering sludge in this system?

A: Sludge generated during treatment is handled via integrated dewatering facilities, which significantly reduce sludge volume and moisture content, making disposal easier, more cost-effective, and compliant with environmental regulations.Q: How is the system maintained and what support is offered?

A: Routine maintenance is streamlined due to robust component selection and automation. Comprehensive technical support, spare parts, and on-site services are available from the manufacturer and service provider to ensure reliable and continuous operation.Q: What are the major benefits of using this wastewater treatment system?

A: Key advantages include high water recovery, compliance with environmental discharge norms, reduced operational costs, minimal noise (<80 dB), flexibility in operation, and a custom-tailored design that fits diverse industrial requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Waste Water Treatment Plant' category

"We are accepting inquiries from Chandigarh, Delhi, Haryana, Uttar Pradesh, Punjab, Uttarakhand."

Send Inquiry

Send Inquiry